June 2016 Edition

RDE-LDV Comes to China

The Chinese Ministry of Environmental Protection (MEP) released its official draft of the National 6th regulation in mid-May, 2016. The final version is expected to be published by the end of 2016, and will follow the framework of its European equivalent regulation, UN/ECE Reg. 49, rev.6, with some modifications governing OBD, ORVR, etc., borrowed from American regulation 40CFR Part 1065.

The current regulation, the National 5th, equivalent to Euro 5, has been adopted by the eleven eastern provinces already; China will fully adopt National 5th by January 1, 2017. After January, 2019, type approval must comply with National 6th, although some provinces may choose to adopt the regulation sooner. National 6th regulation would be introduced under 2 phases, with full implementation enforced by 1/1/2020 and 1/1/2023 for phases 6a and 6b, respectively.

Several significant modifications will be introduced with implementation of the National 6th.

- The most dramatic change to the standards is the adoption of the European Real Driving Emissions (RDE) LDV protocol, which involves actual on-road testing as part of the process. This has had a dramatic effect on the design and development process as well as the vehicle certification process in Europe and can be expected to present significant challenges to Chinese manufacturers and their partners as well. In Phase 6a RDE emission results will be reported for monitoring purpose only. In Phase 6b, full compliance of RDE with conformity factor of 2.1 for NOx and PN will be applied.

- Nine provinces in China have altitude higher than 1500m, which is driving a high altitude requirement to assure that vehicle emissions systems will perform to regulatory standards up to 2400m.

- Finally, the National 6th draft proposes a change of testing cycle to the WLTC, which has become the standard test cycle for European certification.

The National 6th process continues to demonstrate MEP's increasing strength in setting policy. It is promoting self-certification by the vehicle manufacturers, provided they employ acceptable equipment and methods, thereby reducing the role of test centers which have been responsible for type approval in the past.

Secondly, new environmental protection laws, beginning in 2016, will not allow local regulations to govern, although early adoption of the National 6th would be allowed. This is in direct conflict with the Beijing Environmental Protection Bureau, which had issued a local draft regulation with significant differences from the National 6th. Beijing had scheduled implementation in 2017, but it now appears that this may only take place if the National 6th protocol is followed.

Sensors, Inc. has actively marketed and sold its SEMTECH® product line in China since 2008, through its Beijing-based distributor, Dopler ECO-Technologies. The company has worked closely with regulators and customers to provide technical solutions for in-use instrumentation and its applications.

Particle Number Developments in Real Driving Emissions (RDE)

|

|

SEMTECH® CPN

|

The European development of Real Driving Emissions (RDE) for gaseous pollutants is published in the European Journal and the forthcoming additions, and includes particle number limits and the inclusion of cold-start. Recent correlation exercises undertaken at various laboratories clearly demonstrate the significant advances made by PEMS manufacturers in developing robust and accurate particulate number counting analyzers.

The JRC study examined the inter-laboratory errors of the PEMS relative to tail-pipe or CVS PMP measurements and determined potential measurement uncertainties in the region of 50%. With high data yield and good performance the path for this important pollutant to be added to the gaseous components is set for the 3rd work package.

Sensors undertook a three year journey to develop a SEMTECH® module dedicated to particle number measurements using the established measurement principle of a Condensation Particle Counter. Initially, diffusion-charging devices were thought to offer the best case solutions for particle number measurements in in-use applications, but they suffered from a number of shortcomings, including:

- Measurement uncertainty of ± 50%

- Lack of an approved calibration methodology

Accordingly, Sensors embarked upon a three year development program of a CPC-based system which was designed to closely mimic the key technology, features and benefits of standard Particle Number (PMP) systems employed in test cells throughout Europe.

The current SEMTECH® CPN provides exceptional correlation performance against laboratory PMP systems, and was recently calibrated and certified by Ricardo-AEA, Ltd. aerosol laboratories in the UK.

Learn more about the SEMTECH® CPN

SENSOR Tech-CT Post Processor

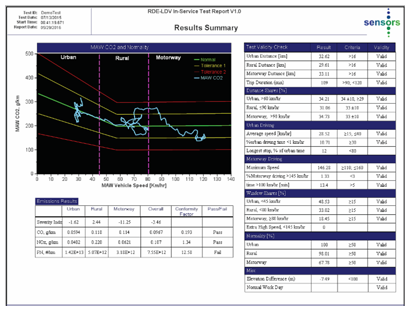

Sensors, Inc. is pleased to announce SENSOR Tech-CT version 1.14 RDE data processing and reporting software. Available now, the software performs all calculations required by both Package 1 and Package 2 amendments of EN 682/2008.

Power binning (CLEAR) method is fully integrated, along with Trip Dynamics and cumulative positive altitude gain calculations which have been validated against EMROAD. In addition, the software now creates all four submission report files as specified in the regulations. Analyzer serial numbers, calibrations, and time alignment values are automatically transmitted from the raw file. A user data entry screen is also provided for vehicle information in the reports.

For more information, contact Sensors, Inc.

In-Use Testing Services

Sensors' designed and manufactured Portable Emissions Measurement Systems (PEMS) equipment is used by our dedicated testing services team to conduct in-use emissions testing solutions. Our experienced staff have measured in-use emissions from a wide range of engines and specialize in custom installation.

Services include:

RDE-LDV

Sensors can perform valid RDE testing in accordance with the requirements of the EC 692/2008, in the presence of an official witness from any of the National Technical Services.

US EPA Heavy Duty

Sensors' service team has conducted over 150 in-use compliance tests for a number of diesel engine manufacturers since 2005.

Fuel Economy

Sensors, Inc. can generate real-world fuel consumption data using PEMS that is as accurate as gravimetric measurements according to SAE J1321 test procedure.

Data Analysis and Reporting

Our test engineers are experienced at using Sensors' own data analysis tools to process emissions data and produce results and reports that comply with the regulatory requirements of the US EPA's 40 CFR part 1065 and European Union's Regulation 49 and EC 692/2008 and their amendments.

Contact us for more information, or read more about our in-use testing services here.