March 2016 Edition

The New European RDE Program Expected to add Particle Number in 2016

On October 28, 2015, the European Commission's (EC) Member States agreed to more robust testing of passenger car emissions in Europe. Beginning September 1, 2017, these will include new Real Driving Emissions (RDE) analysis which will be used in conjunction with the new WLTC test cycle to determine whether new model cars are allowed to be sold in the EU. Moreover, in the next few years, it is very likely that additional work packages will be added to augment the current RDE testing requirements. These may include the introduction of RDE particle number (PN), cold start and in-service conformity testing / limits.

|

|

Figure 1

|

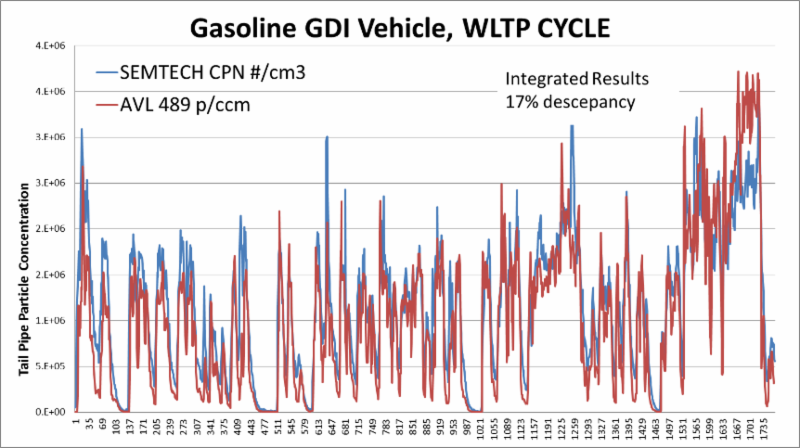

To support the RDE PN program, the EC Joint Research Centre recently completed an inter-laboratory PN measurement campaign involving eight European laboratories, using both Condensation Particle Counters (CPC) and Diffusion Charger on Portable Emissions Measurement Systems (PEMS) with a golden vehicle (Figure 1) and a reference Particle Measurement Program (PMP Regulation 49 and 83) compliant PN device.

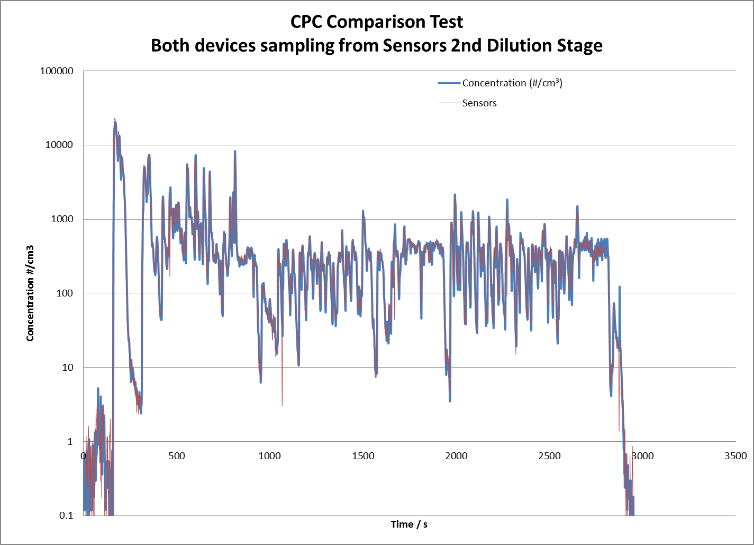

The results, to be published later this year, are expected to confirm their suitability and performance for their inclusion into the RDE regulation (Figure 2). The corresponding EC technical expert group charged with drafting the regulation has reached general agreement on most of the pertinent areas.

Figure 2

- EU PMP validated systems will automatically be approved as RDE PEMS devices.

- If the PEMS utilize CPC technology they can be calibrated using current PMP methodology (including the ISO 27891 standard) or a potentially simplified RDE methodology.

- The calibration procedure for diffusion charger based systems has yet to be determined.

Due to the significant benefits of using CPC based technology for RDE PN measurements, Sensors, Inc. moved from a diffusion charger based system to a CPC system several years ago. These benefits include known calibration techniques and insensitivity to particle size.

To mitigate many of the difficulties in operating CPC technologies outside the laboratory environment, Sensors designed, developed and integrated a CPC / PN module that specifically addressed these concerns; namely temperature, vibration, robustness and "cost-of-ownership". This new module (SEMTECH® CPN) may be supplied with a PMP certificate of conformity.

SEMTECH® CPN has been tested widely in aerosol laboratories (Figure 3), in test cells correlating to reference PMP systems and on road.

Figure 3

The SEMTECH® ECOSTAR Plus Upgrade Now available for ECOSTAR Users

|

|

SEMTECH® Gaseous with ECOSTAR Plus upgrade

|

A number of key new features significantly enhance the user experience, integrating noteworthy advances from SEMTECH® LDV while maintaining the flexibility provided by the ECOSTAR modularity. The enhancement kit is comprised of the Power Distribution and Control Module (PDCM), the In-CAB Module (ICM), more efficient cabling and the SensorTECH-Pro software.

SensorTECH-Pro Benefits:

- System Dashboard: Key parameters are visible at a glance allowing operators to quickly identify issues and rectify them before testing.

- Vehicle Interface (VI) Setup: Auto-discovery of protocol and supported PIDs makes configuration of the VI simple and efficient. Virtually all significant, global protocols are supported.

- Improved communications: Protocols offer enhanced stability and reliability. New protocols establish a unified system time base, faster data download, and improved data integrity.

- Automated Time Alignment: With a single mouse click, the operator can time align the data, and verify correctness with a quick visual check. Further fine-tuning time alignment is completed during post-processing.

PDCM Hardware Benefits:

- In-CAB Control Module (ICM): The vehicle interface is integrated into this control module, The ICM communicates to the PDCM and can interface to third party data acquisition systems such as INCA or CANoe. The module also includes a data marker and emergency stop.

- Heated Line Controller: is now integrated in the PDCM, eliminating the existing heated line control module and reducing cable connections.

- Power over Ethernet: 3 connections enable low power devices or a computer to connect to the system.

- Wireless: Multiple users can control the system from laptops or other smart devices.

- Multi-Channel Power and Communications: Available with four or seven independently switchable power outputs for use with additional modules. (Note: 7-channel units will be required when operated with the ECOSTAR PM systems.)

- Scalability: Modules such as a FID, Dual FID, Calibration or PM may be added to the system as testing requirements expand.

Contact your SEMTECH® sales representative or distributor to discuss ECOSTAR Plus. Call Sensors, Inc. at +1-734-429-2100, Sensors Europe GmbH at +49 (0) 2104-14188-0 or contact us.

New Software Release Incorporates Important Benefits

Sensors, Inc. released new software this month for both the LDV Host and Post-processing suites.

LDV Host Software:

Sensors updated LDV Host software runs from any web browser and features...

- Live driver's aid to help determined RDE test validity on a real-time basis. Distance shares, and special requirements for urban and motorway operation are all displayed and updated each second during the test drive.

- One-click software updates: Users now have automatic software updates to all LDV modules with a single operation. Software updates can be distributed via internet and installed by any user.

- Optional LDV FID: The command interface for the LDV FID is now integrated into the SensorTECH Pro Host software.

- Support for CPN: Pulsations in low velocity exhaust flow measurements have been an industry challenge for decades. Now, in addition to our pneumatic pulsation dampener, our software helps compensate for bias due to pulsations by measuring the magnitude of pulsations. CO2 correlation mass-based results have been measured within 1-3% on engines as small as 1.2 liters with this method.

- Automatic linearity corrections: Data from your linearity audit is now automatically used to relinearize the LDV gas bench if the user chooses.

- Improvements to various GUI functions including time alignment and module connectivity.

LDV Post-processing Software

Sensors is pleased to announce the latest updates to SensorTech-CT LDV post processing software which includes integration of CLEAR calculations. We are currently also adding the RPA calculations and submission reports, and expect these features to be released in mid-April.

Current version (1.13 B8)

- Updated trip validation requirements according to "package 2" of the proposed RDE regulations

- Diadem 2015 support

- FID and CPN support

- Support for ECOSTAR data files

- Added option to compute mass emissions using exhaust flow derived from vehicle MAF sensor plus calculated fuel rate

- Auto detect regional settings

- Added drift analysis results

We are not stopping here. Following the CLEAR calculations this month, we are continuing to add features and functionality to the post-processing software suite and in the coming months look for our release of: Submission Reports and RPA Calculations.

Testing Services RDE-LDV Real-Driving Emissions

For over eight years, Sensors has delivered in-use, on-road compliance testing to heavy-duty engine, vehicle and equipment manufacturers. Over the past 6 months, Sensors, Inc. has further expanded their Testing Services staff and capabilities to meet increased demand and offers a dedicated in-house team to now also provide turn-key RDE-LDV real-driving emission testing as a part of the homologation of light-duty vehicles.

We offer a breadth of services that cover consultancy, on-site support, to taking full ownership for performing valid real-driving emission tests in accordance with the requirements of European regulation EC 692/2008 in the presence of an official witness from any of the National Testing Approval Agencies. Our RDE-LDV real-driving emission test services includes:

- SEMTECH® Gaseous and PN emissions analyzers

- Technical personnel to conduct real-driving emission test

- Development of valid local test route

- Post-processing of emissions data using CLEAR and EMROAD

- Verifiable records to assure compliance with all applicable requirements of EC 692/2008

- Reports for submission to regulatory agencies

We provide RDE testing services in the United States as well as Europe. Please contact Dr. Atul Shah (USA) +1-734-429-2100 or Mr. Oliver Franken (Europe) +49 (0) 2104-14188-0 for further details.

Introducing Sensors, Inc. President & CEO, Joe Morrill

Sensors, Inc. is pleased to introduce Joe Morrill, President & CEO.

Joe joined Sensors, Inc. from PCB Piezotronics, a US-based manufacturer of sensors for test and measurement in an array of markets headquartered in Buffalo, NY. While at PCB Piezotronics for 7 years, Joe served as Vice-President Sales & Marketing as well as, Director of Business Development for Automotive Sensors. Joe returns to the Ann Arbor area where he previously held leadership positions with Moog, FCS COM and Entela, Inc. Classically trained as an engineer early in his career with General Motors, Joe has managed small and medium sized companies since, bringing over 30 years of automotive experience with him.